Electrification of agricultural machinery: VOSS takes proven system solutions to the field

Electrification of agricultural machinery: VOSS takes proven system solutions to the field

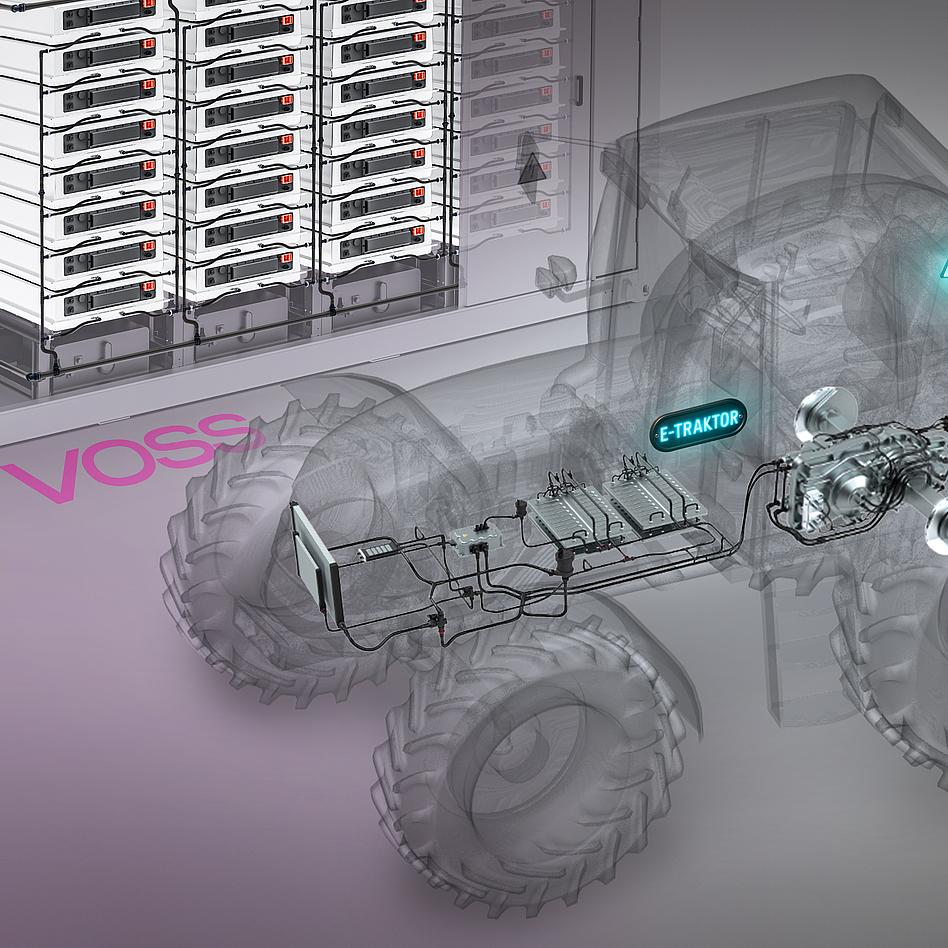

Electrification does not stop at agricultural machinery. However, the extreme operational conditions demand robust solutions. VOSS is actively shaping the transformation of agricultural technology with intelligent thermal management, valve technology, and durable system components.

Components must withstand extreme loads

While battery-electric drives have long been established in the automotive sector, the electrification of agricultural machinery is still in its early stages. Long operating times under full load, extreme temperature fluctuations, dust, vibrations, and a lack of airflow for passive cooling are the challenges facing vehicle manufacturers. In particular, the waste heat generated during hours of harvesting requires efficient thermal management of the batteries.

As a comprehensive system supplier, we develop customized line and connection systems as well as special valve solutions that operate reliably and maintenance-free throughout the entire service life of the vehicles. In doing so, we draw on our decades of experience in the commercial vehicle sector — a vehicle class whose requirements in terms of robustness and service life are similar to those of agricultural machinery.

The solution is thermal management: from space-optimized quick connect systems to immersion cooling

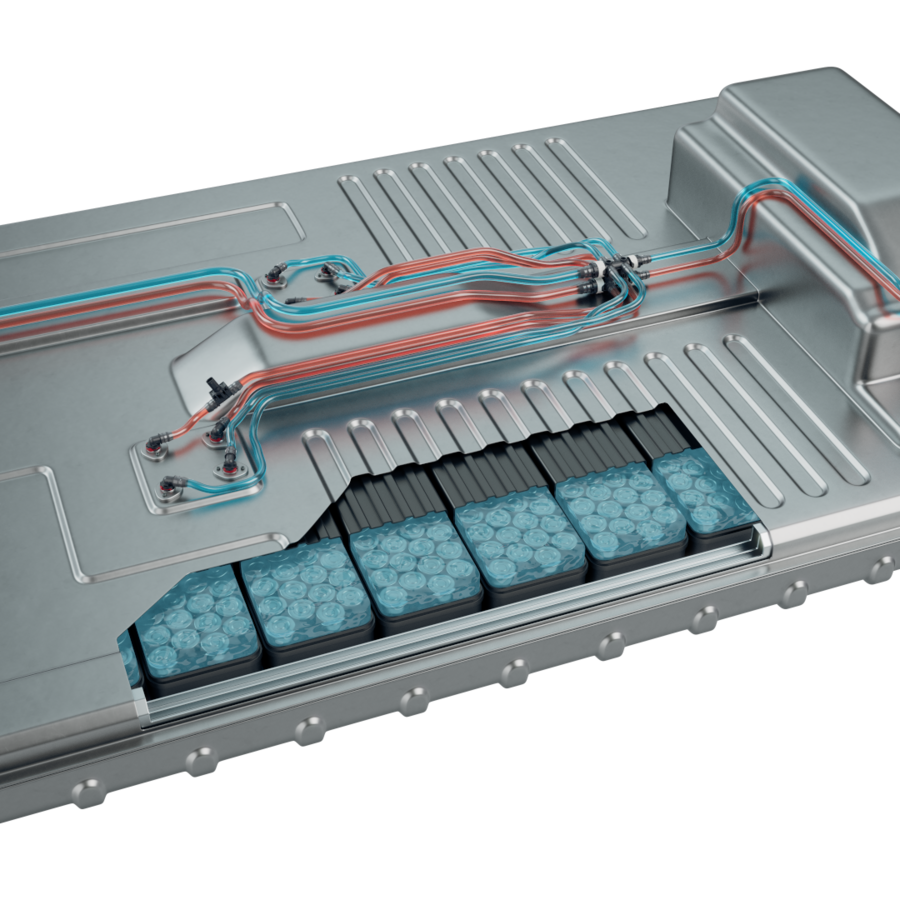

Space-optimized quick connect systems are an essential component of our thermal management systems. They can endure high mechanical loads and impress with their very low installation heights, as well as their space-saving and reliable assembly. They are designed for dynamic temperature changes and ensure permanently tight connections. This enables their use beyond agricultural machinery in passenger cars and commercial vehicles.

Immersion cooling has proven to be a particularly efficient solution for protecting the battery from overheating. In this approach, the powerful energy cells are completely surrounded by an electrically non-conductive liquid. This results in a very even temperature distribution, which significantly extends the service life of the cells – a key factor for reliable continuous operation in agriculture. This active cooling solution requires materials that not only offer high conductivity but are also resistant to ion leaching. VOSS develops specially designed, space-saving quick connect systems made of fiber-reinforced, recyclable plastic for this purpose. They are designed for continuous temperatures from –40 °C to +85 °C.

Efficient cooling through intelligent valve technology

In modern agricultural machinery, different cooling circuits must be precisely controlled — for example, between the battery, power electronics, and interior air conditioning. Our electrically actuated valves regulate the flow of coolants and their distribution between the various components according to demand, which is important for making the energy flow in the vehicle as efficient as possible. They have a modular design and can be configured to customer specifications.

Our valves must meet certain material properties depending on the area of application (e.g., water-glycol and oil). This is particularly relevant for multifunctional heating and cooling systems — for example, for preheating batteries in winter or air conditioning the cabin during long working hours in summer.

From vehicle to energy system – second-life batteries as stationary storage

Electrification in agricultural technology goes beyond single vehicles: stationary battery energy storage systems (BESS) are becoming increasingly interesting for the agricultural industry. They store excess electricity from photovoltaic systems and provide energy for fast charging of work machines, enabling farms to save on the costly expansion of a powerful grid infrastructure.

One forward-looking approach is the use of second-life batteries. The idea is that obsolete electric car batteries, or those that are no longer powerful enough for mobile use, are often still suitable for stationary storage. Here, reliable cooling systems are also essential. Our integrated line systems outlast the use of several battery life cycles and contribute to resource conservation with recyclable materials, detachable connections, and their durability.

Conclusion: VOSS paves the way for electrified agricultural machinery

With our system approach, we connect vehicle technology, energy storage, and environmental responsibility. Thermal management is a key technology in electrified agricultural engineering — both for mobile and stationary energy systems. With well-designed line systems, smart valve technology, and sustainable components, we're laying the groundwork for sustainable agriculture.